Hydraulic operated releasing spear

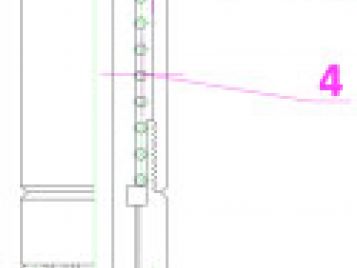

Construction of the releasing spear:

1. Connection part

2. Piston

3. Cylinder

4. Spring

5. Slip set

6. Locator ring

7. Mandrel

8. Control ring

The hydraulic operated releasing spear is used to internally engage and retrieve casing and tubing even if it is not restrained from rotation.

The tool consists of

- mandrel

- piston with piston spring

- slip segments

- locator ring

- control ring

The slip segments are furnished with tapers matching those of the mandrel permitting the slips to travel down on the mandrel, thereby expanding their outside diameter as they reach the fish. The position of the control ring is adjustable limiting the slip's movement according to the inside diameter of the fish. The locator ring prevents the spear from being run too far into the fish. The tool can be assembled with different sizes of slips and locator ring for different sizes of casings from 4 1/2" to 9 5/8". For smaller sizes separate size releasing spear shall be used.

Before running in the releasing spear, check that the correct size slip segment and locator ring are assembled, and adjust the proper position of the control ring:

- make the spear up to the end of fishing string

- run the releasing spear in the hole to the top of fish

- lower it slowly until the locator ring meets the top of fish

- starting the pump a pressure drop is created across the piston which forces the slips downward and brings them in the catch position

- by elevating the fishing string while circulating the slips bit in the fish and heavy strains can be applied to free it

- in back-off operations: the slips should first be set by pulling strain on the string

Then the strain is adjusted to bring the neutral point to the desired depth and left hand torque must be applied. The spear can be released from the fish by bumping down. This will re-engage the slips and the piston spring keeps the slips in released position and the tool can be elevated from the fish.